Product display

Contact Information

Fax: 025-84981642

Address: No.5, Rungu Road, Guli Industrial Park, Jiangning District, Nanjing City, Jiangsu Province

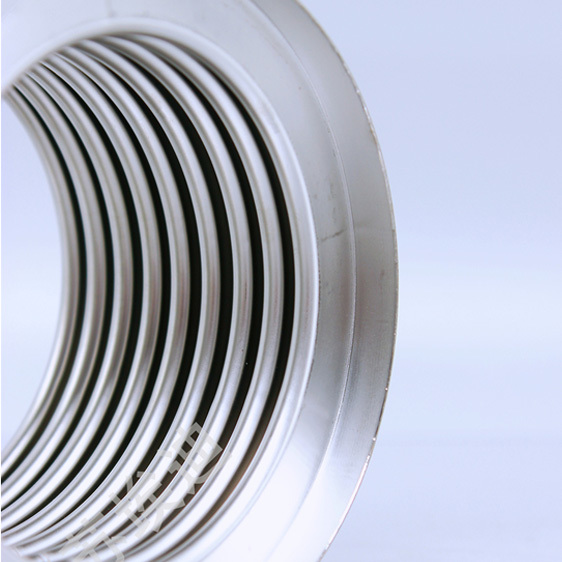

Metal bellows

Key words:

Classification:

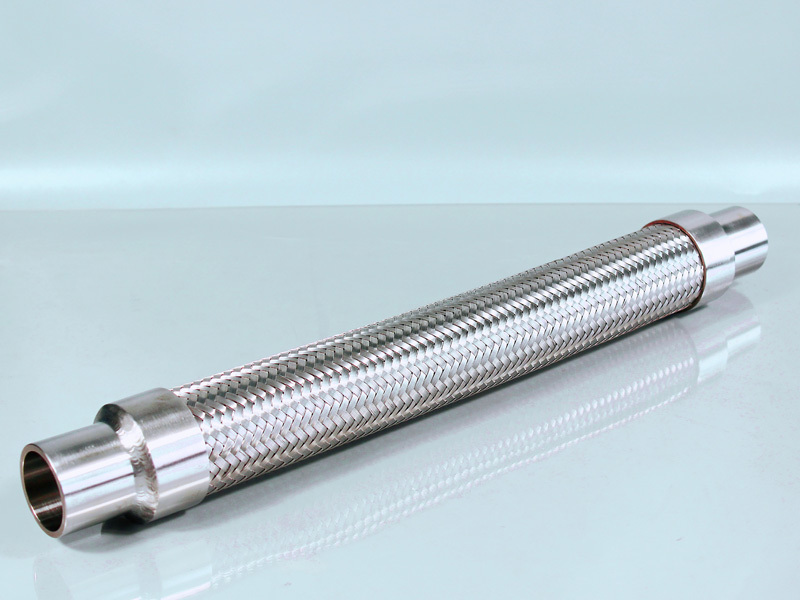

Various port types of metal bellows

|

Port corrugation flattening

|

Port outer roll 90 degree flanging

|

Straight port

|

|

Port Blind |

Port Flaring |

Both end ports can be combined arbitrarily |

We are good at making thin-walled multi-layer metal bellows, the thinnest wall thickness of up to 0.1mm, up to 18 layers of thin-walled multi-layer metal bellows its comprehensive performance is better than the traditional thick-walled corrugated pipe.

|

|

|

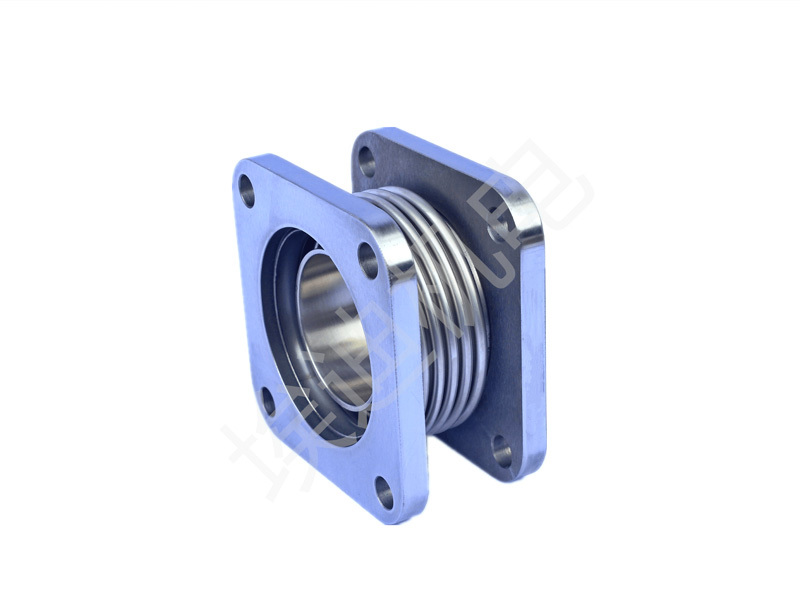

Displacement compensation function

Compensation equipment, pipeline displacement in each direction, which is equivalent to a closed spring

|

radial displacement |

Axial displacement |

angular displacement |

At the same time can be axial, radial, angular displacement |

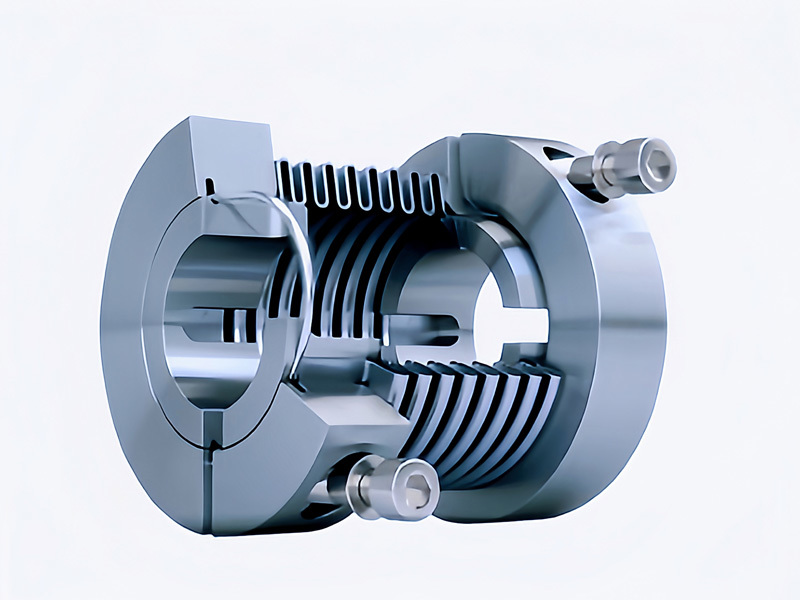

Metal bellows dynamic sealing function

The metal bellows can transform the axial dynamic seal into the end face static seal, thus effectively solving the leakage risk caused by the long-term use of the traditional dynamic seal

|

|

|

Metal bellows face dynamic seal function

The end face mechanical dynamic seal can be realized by using the internal pressure thrust and stiffness force of the metal bellows, and the size of the end face sealing force can be controlled according to the pressure and parameters of the bellows.

|

|

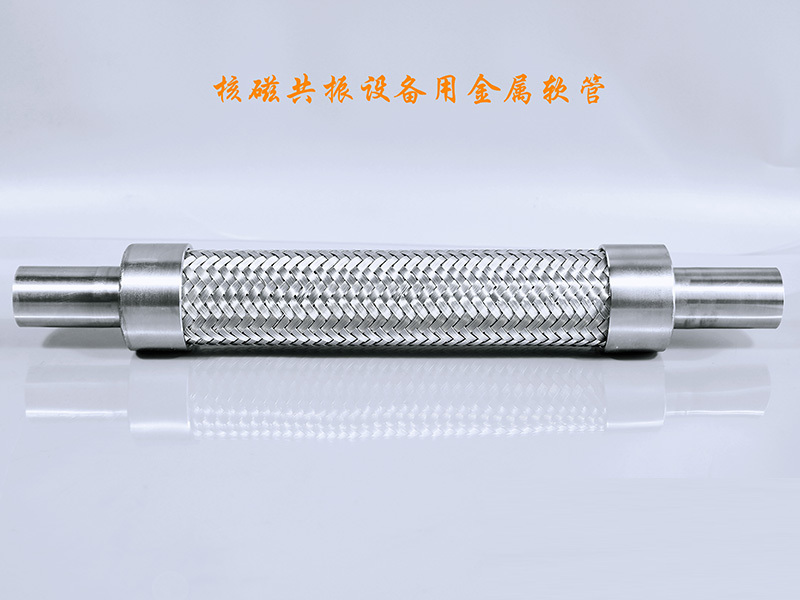

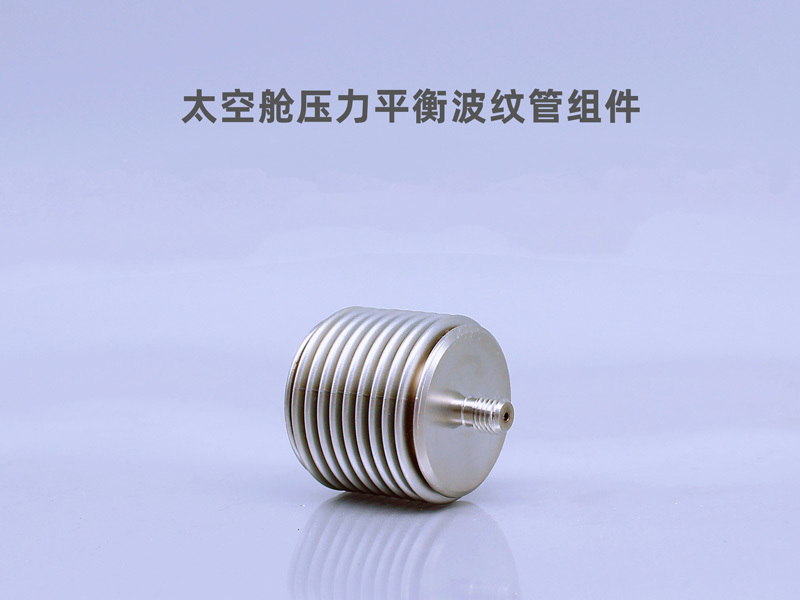

Sensor function of metal bellows

The change of bellows length and the change of stiffness force generated by the internal pressure thrust of the bellows form the corresponding relationship of pressure/force/displacement, which can be used to make a sensor.

|

|

|

|

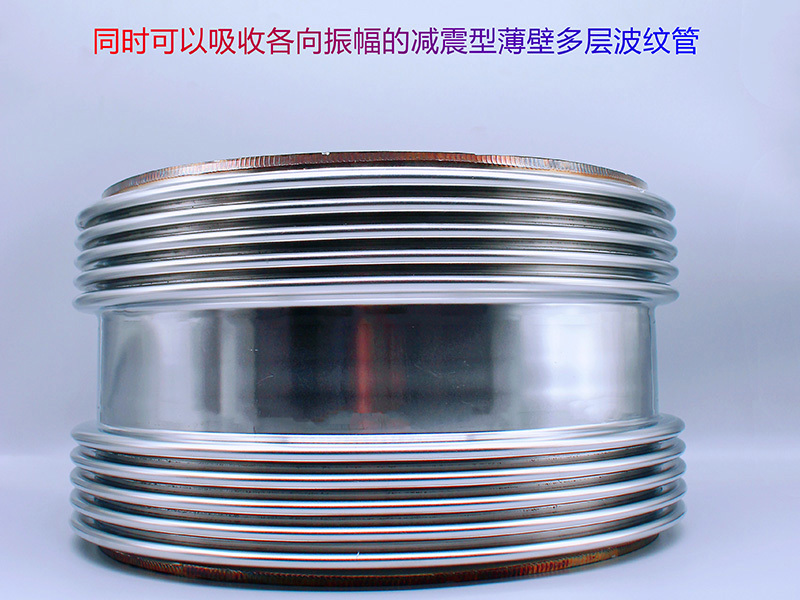

Metal bellows shock absorption function

Thin-walled multi-layer corrugated pipe has superior damping effect. According to the characteristics of the source and the direction of the pipeline, it is a problem that the manufacturer must consider for the customer to select the appropriate shock absorption scheme to avoid the resonance between the metal bellows and the vibration equipment and to minimize the force on the circumferential weld of the bellows.

|

|

|

|

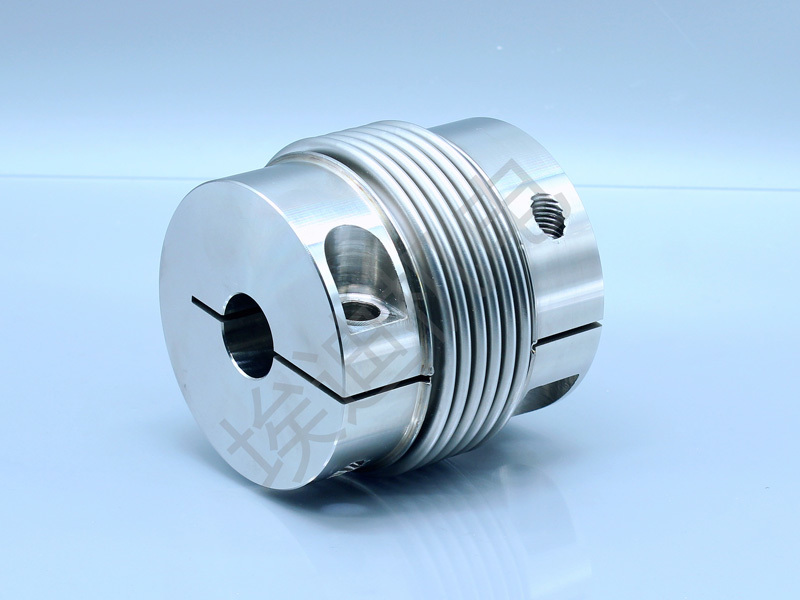

Application of Metal Bellows in Coupling

The use of metal bellows coupling torque transmission to eliminate the rigid impact, can achieve no gap transmission torque.

The coaxiality at both ends of our metal bellows can be as high as 0.15, reaching the international advanced level.

|

|

|

More than 30 years of experience in piping system compensation scheme design brings more safety experience to customers.

Product Ordering Considerations

Dear customer: When you have a purchase plan or in the product design stage, please read the following precautions carefully to ensure that you can purchase satisfactory products in time.

1. Due to product specifications, variety, the company does not provide in stock, are customized according to customer needs;

2. For metal corrugated pipe products, please customers try to design products according to our existing materials and molding mold parameters to reduce the production cycle and avoid unnecessary mold investment.

3. When customizing the corrugated pipe assembly with welded metal bellows and structural parts at both ends, you can safely hand over the complete assembly to our production in order to provide complete products efficiently. The structural parts can also be provided by the customer, which will be provided to the customer after we weld the corrugated pipe group and factory test. In this case, the welding port of your structural part must meet the special welding process requirements. You can confirm the structural design scheme of the welding part with our technical department.

4. We have a wealth of industry product application experience, can provide customers with bellows application solutions. When you have difficulties in product design, you can contact our business representatives so that our technicians can help you with the design. However, you need to provide the functions that the product needs to achieve, the working conditions of the product, the drawings of the structural parts at both ends of the bellows, the technical parameters and expected service life of the product, and special technical requirements.

5. When the product you order is a new product for development and we have no similar successful cases, or when you have strict requirements on product quality, both parties can sign a research and development or trial production contract first, and then carry out later cooperation after you confirm that the sample meets the requirements.

6. Please put forward the complete technical requirements and quality requirements of the products to us when both parties discuss the technical scheme and technical requirements. These requirements should be signed and confirmed by both parties and implemented in the technical data as an annex to the contract. On this basis, I have just made an offer. If new technical and quality requirements are added after the contract comes into effect, the contract may not be performed normally.

7. For high-strength, high-nickel bellows materials, the price difference between imported materials and domestic materials in developed countries is large, please choose carefully and screen carefully.

8. Regarding the purchase of metal expansion joints, you must provide the type of product or the product name commonly known in the industry (e.g. general type, external pressure type, angle type, universal angle type, small tie rod type, large tie rod type, curved pipe pressure balance type, etc.), the connection mode at both ends of the product, the pressure grade, compensation amount, fatigue life, temperature, material, etc. of the product. You can also contact our technicians, and we will help you with the design of pipeline compensation scheme and the selection of expansion joints.

9. The safe use of metal expansion joints is closely related to the setting and load check of equipment or pipeline supports. Please refer to the company's sample and metal expansion joint standards for detailed requirements.

Related Products

Get a free quote

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

To: Company Name